1. Product description

Washers DIN 125 form A are flat washers made of materials such as steel or stainless steel, which ensure an even distribution of the force exerted on the linking element. They are specifically designed to increase the contact area between the bolt head or nut or cotter pin and the component to be fastened, reducing the risk of material damage and preventing sinking. These washers are standardized, without chamfer, and comply with DIN standard 125 form A, which makes them suitable for a wide range of industrial and craft applications.

2. Product details

Size: 2,7 - 50

Material group: Steel, stainless steel, stainless steel A4 quality

Surface: bright, electr. galvanised white

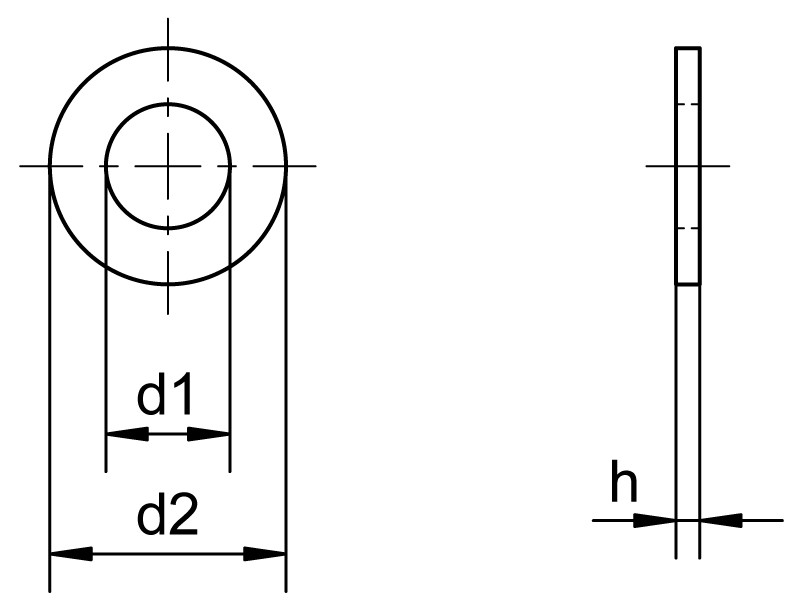

d1 Internal diameter: 2,7 - 50

d2 External diameter: 6 - 92

h Height: 0,5 - 8

3. Application Areas & Compatibility

Metalworking: In metalworking, these washers play an essential role in the assembly of machine parts, metal constructions, and fastening technology. They enable efficient load distribution in screw connections or in combination with bolts with pin hole and cotter pins DIN 94, which increases the integrity of the processed metal components.

Construction: In the construction industry, they are used to evenly distribute pressure on fastening points of building elements. This is particularly relevant when assembling roof structures, wooden beams, and in facade construction techniques, where precise load distribution is essential to maintain structural integrity.

Mechanical and plant engineering: In mechanical engineering and plant construction, they enable reliable and durable connections of critical components. The standardized shape and the different available materials ensure that a suitable washer is available for almost every requirement.

Furniture Industry: In furniture manufacturing, these washers provide stable connections during assembly. Especially in the production of office, garden, and kitchen furniture, where screw joints are frequently used, they ensure the stability and longevity of the furniture pieces.

Renewable energy: In the renewable energy sector, especially when installing solar panels and wind turbines, they ensure even distribution of mechanical loads caused by wind and weather influences. This increases the reliability and lifespan of these systems.

Electrotechnology and electronics: Due to their precise compliance with standards and the ability to provide or minimize electrical conductivity (depending on the material), they are important in electrical and electronics manufacturing for fastening and grounding components.

Maintenance and servicing: In the maintenance and servicing of a wide variety of equipment and plants, washers DIN 125 form A are used to prevent wear at connection points. Their use helps reduce the need for frequent maintenance interventions and contributes to the longevity of the equipment.

Compatibility

The universal applicability of washers DIN 125 form A makes them a valuable component in many industries where precision, reliability, and durability of connections are required. Their compatibility with numerous screw and nut sizes, as well as bolts and cotter pins DIN 94, ensures a wide range of applications in a diverse spectrum of industrial and craft uses.

4. Advantages and Benefits

Improved surface protection: By evenly distributing the pressure exerted by screws or nuts or bolts and cotter pins DIN 94, these washers help minimize the risk of surface damage to the mounting material. In particular, sinking and scratching of screw heads and nuts or cotter pins into softer materials is prevented, leading to longer service life and better visual appearance of the components.

Optimal load distribution: Even load distribution is crucial to avoid peak stresses that could damage the structure or material. Washers DIN 125 form A ensure that the pressure generated by screw connections is effectively distributed over a larger area, increasing the structural integrity of the assembly.

Increased connection security: The stability of a screw connection is essential for the safety of the entire construction. The use of these washers reduces the risk of loosening a connection due to vibration or dynamic loads, ensuring long-term security and reliability.

Versatility in application: Due to standardization and availability in different materials, these washers are suitable for a wide range of applications. This enables their use in almost all areas of industry and craftsmanship where reliable mechanical connections are necessary.

Corrosion protection: When using washers made of corrosion-resistant materials or those with a corrosion-protective surface treatment, the durability of the connection can be significantly increased. This reduces maintenance requirements and the cost of replacing components.

Simplicity and cost-effectiveness: The use of standardized washers according to DIN 125 form A reduces the costs and complexity of procurement and storage. This contributes to efficiency in assembly processes, as they are readily available and compatible with standardized screw and nut sizes as well as bolts and cotter pins DIN 94.

In summary, washers according to DIN 125 form A make a significant contribution to improving assembly quality, prolonging the lifetime of connections, and reducing maintenance requirements and costs. Their easy integration into existing design and assembly processes makes them an indispensable component in many technical applications.

5. Assembly and Installation

The assembly and installation of washers DIN 125 form A are generally uncomplicated in execution, but there are some important aspects to consider in order to ensure optimal function and performance. Here is a detailed look at the essential steps and considerations:

1. Preparation: Make sure that the parts to be connected are clean, dry, and free of dirt or corrosion. This ensures an even bearing surface for the washer and prevents future corrosion or loosening.

2. Selecting the correct size: Choose a washer that matches the diameter of the screw or nut, or bolt, and cotter pin being used. The washer should be sized such that the outer diameter is sufficiently large to distribute the load evenly, without protruding excessively beyond the fastening element.

3. Positioning: Place the washer between the screw head or nut or cotter pin and the assembly material. For applications where there is high load transfer on both the screw and nut sides, using washers on both sides can be beneficial.

4. Tightening: Insert the cotter pin through the cotter pin hole and bend both ends, or tighten the screw or nut with the appropriate tool. Observe the recommended tightening torque, adjusted for the specific application and material properties. Correct tightening torque ensures that the connection is neither too loose (which could lead to vibration and loosening) nor too tight (which could damage the material or overload the screw).

Additional considerations:

Material compatibility: Ensure that the washer material is compatible with the parts to be joined to avoid galvanic corrosion.

Use under dynamic loads: In applications with high vibration or dynamic forces, it may be necessary to use locking elements such as spring washers or locknuts in addition to the washer, in order to maintain a stable connection over time.

Repeated use: Note that some washers, especially those made from softer materials or with special coatings, may not be suitable for multiple uses as they may deform when tightened.

By following these guidelines, you can ensure that the assembly and installation of washers DIN 125 form A is carried out effectively and optimally for the intended application, maximizing the lifespan and reliability of the connection.

6. Safety instructions & Standards

When handling and installing mechanical fasteners such as washers DIN 125 form A, certain safety instructions must be observed. These measures help minimize the risk of injury and ensure safety during assembly as well as the reliability of the connections.

Wear hand protection: Suitable gloves should be worn to protect against sharp edges or surfaces on the washers and other fasteners.

Eye protection: When using tools to tighten the fasteners, safety glasses should be worn to protect against flying debris or material splinters.

Use appropriate tools: The installation tool should match the size and type of fasteners to avoid both damage to the linking elements and injuries.

Tool handling: Always make sure you have a secure footing and a firm grip on the tool to prevent slipping.

Observe tightening torque: Over-tightening fasteners can cause material fatigue or damage to the connections. Insufficient torque can lead to loose connections. Therefore, it is important to observe the recommended tightening torque, which is suitable for the respective materials and the specific application.

Check material compatibility: Incompatibility between the materials of washers, screws/nuts, bolts/cotter pins, and the components to be joined can cause corrosion. It is important to ensure that all materials used are compatible with each other.

Consider specific requirements: In certain applications, such as in damp environments or areas with high chemical exposure, special fasteners and washers should be used that are designed for these conditions to ensure durability of the connection.

Regular maintenance and inspection: Regularly check the integrity of the connections, especially in critical or highly loaded areas, to detect wear or potential failure risks at an early stage.

Following these safety instructions helps to minimize the risks that can arise during the handling and assembly of washers and other fasteners, thus creating a safe working environment.

Standards

DIN 125: DIN 125 specifies the geometric shapes, dimensions, and tolerances for washers. Compliance with this standard guarantees universal applicability and interchangeability of washers, thereby contributing to optimized compatibility and functionality during installation.