描述

1. Product description

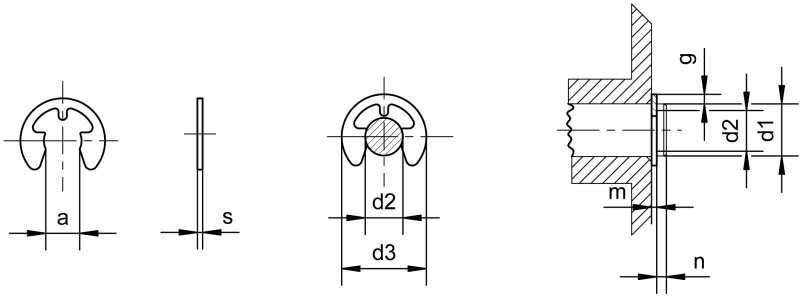

The Locking washer DIN 6799, also known as retaining ring or E-retainer, is a precision-engineered retainer made of steel or stainless steel, commonly used for securing rotating components, bearings, or gears on axles and shafts. Locking washers according to DIN 6799 are mounted on bolts, axles, or shafts with groove or spline, thus preventing axial displacement. The unique aspect of the locking washer DIN 6799 lies in its minimalist design, which provides maximum holding power despite its simplicity. This allows for use in a variety of applications, from light to heavy-duty connections. The specific E-shape of the locking washer ensures that it maintains its position even under high loads or vibrations, providing permanent and reliable securing. In addition to its high functionality, the DIN 6799 locking washer is impressive for its economic efficiency. Its standardization according to DIN norms ensures that it is available in a wide range of sizes and specifications to meet diverse technical requirements.

2. Product details

Size: 2,3 - 19

Material group: Steel or stainless steel

Surface: bright, mech. galvanised silver, phosphatised oiled

3. Application Areas & Compatibility

The locking washer DIN 6799 proves to be an extremely versatile retainer that is used across a wide range of industries and applications. Its robustness and reliability make it the preferred fastening element in many critical and demanding applications.

Mechanical and plant engineering: In mechanical and plant engineering, locking washers DIN 6799 play a key role in retaining rotating components, bearings, or gears on axles and shafts. Here, they enable precise and firm fixation of components, which is indispensable for smooth functioning and longevity of the machines. Their use helps to minimize downtime and reduce maintenance costs.

Agricultural equipment: In agriculture, where equipment is exposed to extreme conditions and loads, the DIN 6799 locking washers offer a reliable solution for fastening and securing components. From tractors to harvesters, they ensure the performance and reliability of the machines, preventing parts from coming loose, which is particularly important during the harvest season.

Everyday applications: The versatility of DIN 6799 locking washers is also reflected in a number of everyday applications. They are used in household appliances, bicycles, and even sports equipment, where they perform important functional and safety-related tasks. Their ease of use and reliable performance make them a practical solution for numerous fastening requirements in the private sector.

4. Advantages and Benefits

Easy and quick assembly: A significant advantage of the locking washers DIN 6799 is the straightforward and fast assembly with or without tools, with the use of the special assembly tool making the assembly easier. This fastening element can easily be inserted into the designated groove. This feature not only saves time during assembly but also reduces costs as no special equipment or skills are required. The easy handling facilitates mass assembly, which is especially valuable in industrial production. Dismantling is easy and can be done with a screwdriver, for example.

High retention force and reliability: Due to their special design, the locking washers DIN 6799 generate excellent retention force, effectively holding the components in place. This retention force remains even under demanding conditions and vibrations, ensuring a secure and reliable connection. This feature is particularly important in applications where safety and functionality are prioritized.

Durability and maintenance-free: Made from high-quality materials such as spring-hardened steel or stainless steel, the locking washers DIN 6799 offer excellent durability and corrosion resistance. These features ensure that the washers maintain their functionality even under continuous use in aggressive environments without the need for replacement or maintenance. This minimizes operating costs and increases the reliability of applications.

Improved safety: The design and functionality of the locking washers help to minimize the risk of unintentional loosening of components. This improves the overall safety of machinery and equipment, helping to reduce potential hazards for users and the environment.

5. Assembly and Installation

Step 1 - Preparation: First, ensure that the axle or bolt on which the locking washer DIN 6799 is to be installed is free of dirt, oil, and other contaminants. This guarantees optimal holding force of the locking washer DIN 6799.

Step 2 - Positioning: The locking washer DIN 6799 should be positioned in the correct orientation to the groove on the axle or bolt. Make sure that the embossed edge of the washer is correctly aligned to allow proper snapping into place.

Step 3 - Installation: Now, carefully but with sufficient pressure, press the locking washer DIN 6799 into the groove of the axle or bolt. The installation can be done with or without an assembly tool, but using the special assembly tool simplifies the process. The procedure is complete when the locking washer DIN 6799 is fully snapped in and flush with the surface of the groove base.

Step 4 - Verification: After installation, it is recommended to check the locking washer DIN 6799 for correct fit and full engagement. A properly installed locking washer DIN 6799 will be firmly in place and cannot be removed without applying targeted force.

6. Accessories and Extensions

For the locking washer DIN 6799, a specific assembly tool is available to facilitate installation in hard-to-reach areas.

Frequently Asked Questions (FAQ)

What is the locking washer DIN 6799 and what is it made of?

For which applications is the locking washer DIN 6799 particularly suitable?

What are the advantages of the locking washer DIN 6799?

How is the assembly of the locking washer DIN 6799 carried out?

Why is it important to regularly inspect locking washers DIN 6799 and what measures should be considered during care and maintenance?

What materials are used for the production of locking washers DIN 6799?

How do you determine the size of the locking washer DIN 6799 for a specific application?

A great help for the proper design of the groove or indentation is the mbo Osswald bolts configurator with groove.

Can locking washers DIN 6799 be reused?

What is the significance of locking washers DIN 6799 for the general safety of machinery and equipment?

What alternative retainers for shafts with groove or spline are there?

SL-retainers are play-compensating and only suitable for shaft ends. Available only in steel.

KL-retainers are play-compensating, easy to install and remove. Available only in steel.

Bayonet clips are only usable at the shaft ends and have an additional tab that clamps the clip onto the shaft end. Available only in steel.

Retaining rings DIN 471 are simple and frequently used retaining elements for bolts and shafts with a groove. Wide range from 4mm to 60 mm in steel and stainless steel. Installation and removal using special assembly tool.