Axle manufacturing at mbo Osswald

Axles are central mechanical components that serve as supports or pivot points in a variety of applications, from automotive engineering to mechanical engineering. They transmit motion, bear loads, and are critical to the stability and functionality of machines. A axle typically consists of a cylindrical body that can be either stationary or rotating, depending on the specific application. Our production of custom axles according to customer specifications or technical drawings ensures these critical components are optimally tailored to the requirements to be met.

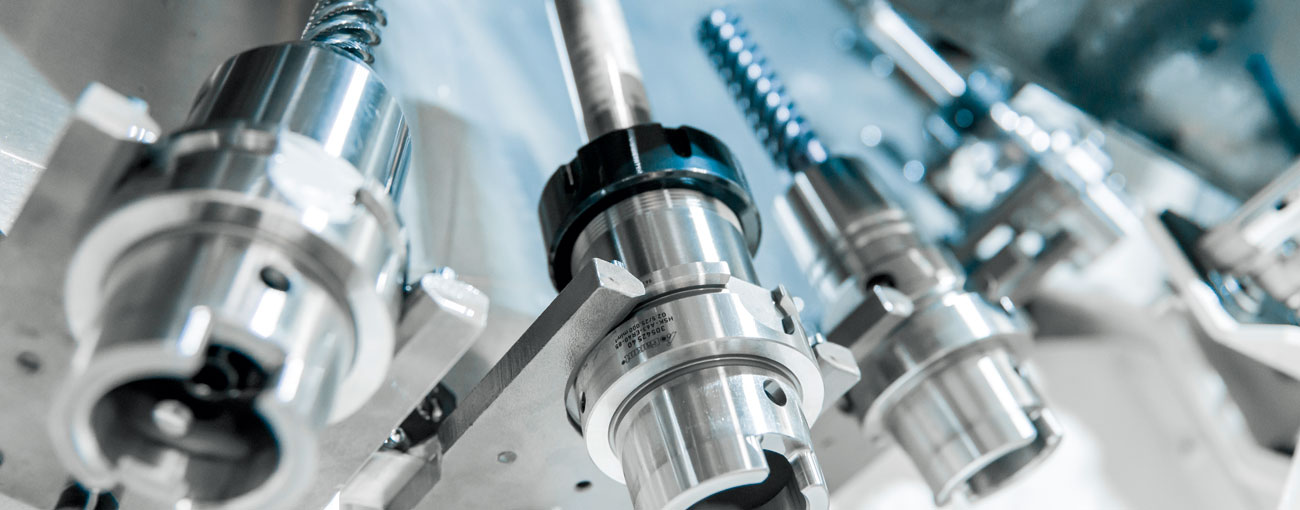

Thanks to advanced manufacturing methods, we can produce complex axle geometries and meet precise specifications. This enables adaptation to specific use cases, with different materials available to ensure suitability for a wide range of environments, such as corrosive or high‑load conditions.

Axles are indispensable in the design and maintenance of machinery, as they act as the pivot and focal point for movement sequences. Their versatility and load-bearing capacity make them an ideal solution for a broad range of applications that demand long-lasting and effective performance.

Application areas of axles according to drawing

The diverse application areas of axles manufactured to drawing reflect the central importance of these components in the modern technical environment. Depending on the field of application, axles are designed individually to reliably perform specific tasks in industrial systems and machines. They are used wherever, in addition to pure mechanics, there are requirements for precise motion guidance, high load capacity, or special operating conditions. By designing according to drawings, it is possible to technically adapt axles exactly to the respective environmental parameters and functional requirements – be it in terms of geometry, material, or surface condition. This high degree of customization not only ensures optimal performance but also increases service life and safety within the given application. Thus, the fields of application for tailor-made axles extend from standardized machines and systems through the automotive and agricultural sectors to highly specialized solutions in energy and conveying technology, with each area bringing its own design and operational challenges.

Mechanical engineering

In mechanical engineering, axles are essential components responsible for motion control and the stability of machines. They are used in large production machines to precisely guide movements while carrying heavy loads. One example is CNC machines, where axles ensure accuracy in the machining of workpieces. Axles are also of crucial importance in presses, as they serve as stable pivot points that must withstand extremely high compressive forces.

Vehicle construction

In vehicle construction, axles are indispensable components that provide stability, mobility and performance. They are essential parts of wheel suspensions, drivetrains and steering mechanisms. Front and rear axles take on the task of supporting the vehicle’s weight and efficiently transferring engine power to the wheels, which is particularly important for ride comfort and safety. In commercial and heavy-duty vehicles, axles are specifically designed for the high loads encountered during transport and off‑road use. Overall, axles make a decisive contribution to the functionality and efficiency of vehicles.

Agricultural engineering

In agricultural engineering, axles are used in various machines, for example in tractors, combine harvesters and plows. These machines depend on robustly constructed axles to guarantee their functionality in demanding environments such as uneven terrain or large temperature fluctuations. Axles enable the reliable transmission of drive and steering forces while also providing the necessary stability.

Energy generation

In the field of power generation, axles play a central role, especially in wind turbines. They ensure the secure connection of the various turbine parts and enable the rotational movement of the rotor blades. The material of the axles must be particularly corrosion-resistant to withstand demanding conditions such as wind and moisture and to ensure a long service life of the installations.

Conveyor technology

In material handling, axles are indispensable for supporting the movement of heavy goods in production plants, warehouses, and distribution centers. They primarily serve as load-bearing elements in roller conveyors, conveyor belts, and transfer carts. They ensure not only the stability of the conveyor systems but also smooth movement to maximize efficiency and throughput.

Construction and building technology

Axles accorting to drawing ensure precise, long-lasting connections in construction and building technology – from facade and parapet elements to gate systems and ventilation dampers. Individually defined geometries, fits and surface finishes ensure play‑free support, corrosion‑resistant operation and a long service life. By using suitable materials and tolerance chains, assembly times are reduced, maintenance is simplified and system efficiency is noticeably increased.

Machining areas and materials in axle manufacturing

The machining capabilities and materials used in axle manufacturing largely determine how flexibly and precisely axles can be produced to suit the specific application. Modern manufacturing technologies make it possible to cover different shapes, dimensions and quantities, thereby providing the right solution for both single-piece and series production. In this context, the selection of suitable materials – from conventional undercut steel to high-quality stainless steels and specialized alloys – plays a decisive role for the durability and reliability of the axles.

This variety allows axles to be tailored individually to a wide range of technical challenges and environmental conditions. A broad spectrum of machining options further ensures that special design requests and industry-specific requirements can be implemented reliably.

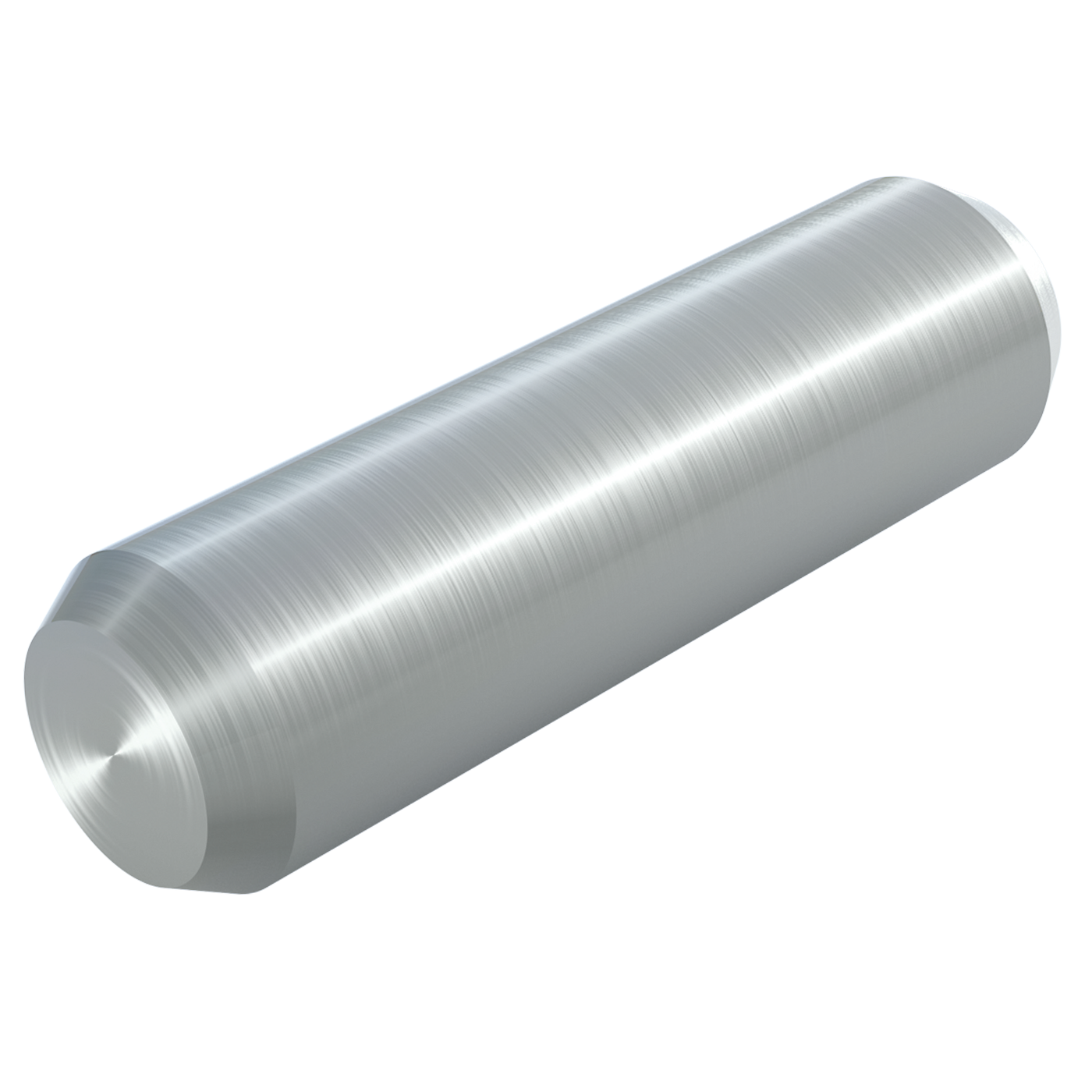

Various shapes and lengths for any quantities

For axles made to drawing, we offer a wide selection of diameters from 4 mm to 65 mm and lengths between 5 mm and 350 mm – optimally matched to a wide range of applications across various industries. With this flexibility, both single bespoke items and large series projects can be realized. Whether small batch sizes for special machine solutions or large quantities for series assembly are required: our production is designed to implement your individual requirements reliably and efficiently.

Simply tell us the desired quantity and the technical specifications of your axles – we will ensure a tailored implementation, whether it is a special solution or a series component.

The most common materials: steels of varying quality

For the production of bespoke axles according to drawing, we rely on a wide range of materials that are specifically matched to the respective application requirements. In particular, we use high-quality steels – from undercut steel through A2- and A4-quality stainless steel to selected special steels.

Depending on the load profile or environmental conditions, we can also use materials that offer particularly high strength, optimal corrosion resistance or special properties such as seawater resistance or high-temperature strength. This ensures that each axle is optimally prepared for its intended application both mechanically and in terms of service life – and that you receive the right material basis for every technical challenge.

Axles according to drawing – machining options

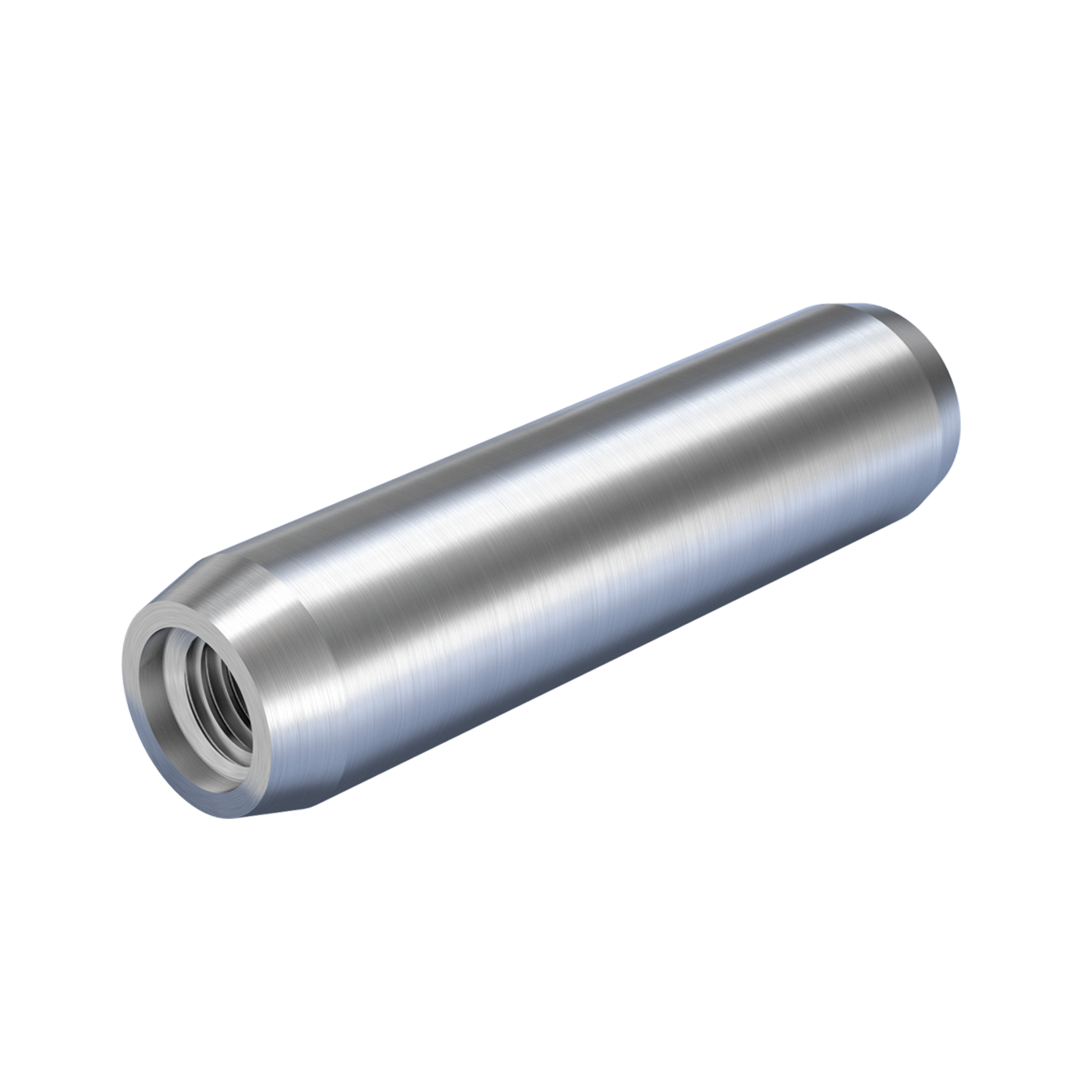

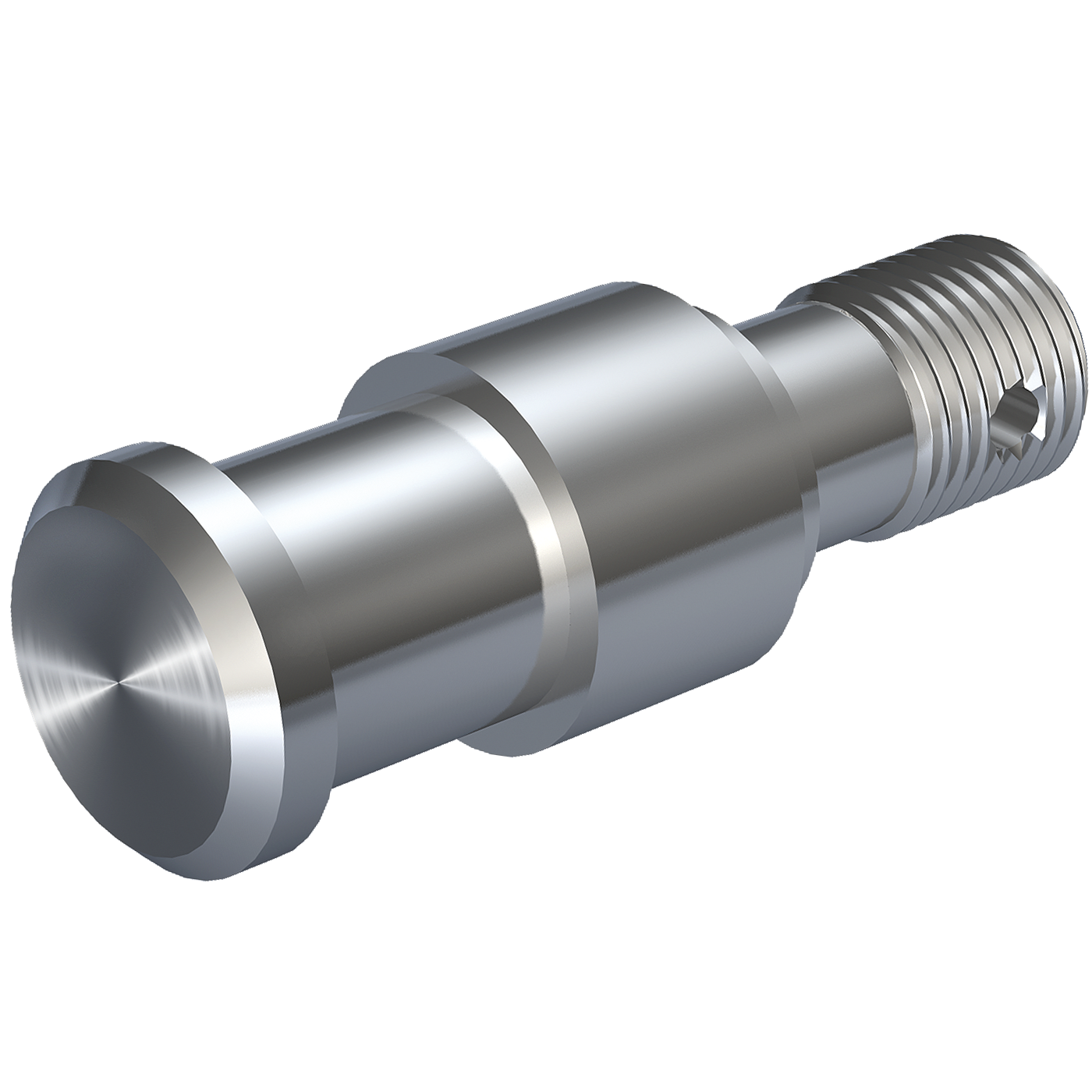

Axles can be adapted to specific application requirements in many ways thanks to modern manufacturing techniques. A wide range of machining options allows both functional and design-specific features to be implemented reliably. Typical options include cross holes, grooves, various milling operations and polygonal turning. Special head forms such as spanner surfaces or internal hexagon can also be realized. In addition, numerous types of threads – metric or inch, in regular, fine-pitch, right- or left-hand versions – are available to optimally adapt the axle to the respective application.

Complex geometries can be implemented just as well as the individual marking of individual components for clear identification. With this broad range of options, tailor-made axles are ideally suited to demanding technical challenges where standard solutions reach their limits.

Various surface finishes for your axles according to drawing

Surfaces play a central role in axles according to drawing, as they significantly contribute to functionality, longevity and resistance to external influences. Depending on the intended area of application – for example in corrosive environments, under high mechanical loads or with specific cleaning requirements – the surface treatment can be selected individually. The goal is to optimally protect the axles from environmental effects, increase their load-bearing capacity and achieve specific technical properties.

Coating

In addition to various functional special surface treatments, we in particular carry out electroplated coatings such as the galvanic zinc plating. In this process, a thin layer of zinc is applied to the surface of the axle, which serves as an effective corrosion protection and reliably protects the underlying material from penetrating moisture. Further options, such as phosphating, passivating or bluing, are also available for specific application requirements.

Treatment

Depending on the intended application, it may be necessary to treat the axle surface specifically: for particularly clean applications, axles are supplied completely grease-free, while in other cases a defined oil film can be applied for temporary protection and easier handling. This decision will be made individually together with you and is based on the planned operating conditions of the axle.

Mechanical processing

To achieve exact tolerances and highly smooth surfaces, we offer grinding as a precise, machine-based process. (laser) engravings and individual markings are also possible, which can serve both traceability and specific documentation requirements.

Finishing

The targeted modification of material properties is achieved through processes such as heat treatment. For example, hardening significantly increases the surface and core strength of the axle, while quenching and tempering produces a particularly balanced combination of high strength and toughness. By nitrocarburizing, the axle's surface layer is additionally improved against wear and corrosion. These heat-treatment measures overall ensure an optimal adaptation for demanding and long-lasting applications.

The special axles at mbo Osswald

At mbo Osswald you benefit from exceptional manufacturing expertise, which offers a wide range of special axles according to drawing. The product range includes, among other things, fit axles, hollow axles, stepped axles, pin axles, axles with various head and end shapes, as well as models with targeted machining such as spanner surface, cross hole or threads.

Furthermore, axles with specific adaptations – for example for special installation situations, particular load profiles or industry-specific requirements – can be realised at any time. The diversity in turned-part manufacturing makes it possible to implement both classic standard axles and highly customised individual solutions quickly and efficiently. This way you receive at mbo Osswald precisely the shaft that best fits your application and your project.

Specialist in axle manufacturing to drawing: Precision tailored to your individual requirements

We manufacture turned special axles precisely according to your specifications, samples or technical drawings. Modern manufacturing processes and advanced quality controls ensure the precise implementation of all technical features as well as your specific requirements at all times. Thanks to decades of experience in machining complex, ready-to-install turned and milled parts, mbo Osswald provides you with a comprehensive full-service at the highest level.

Our portfolio covers all process phases: from the initial analysis of your specifications through production tailored to the material up to flexible logistics – everything from a single source, exactly in the desired quality and quantity and delivered on the agreed delivery date. On request, we also take care of assembly, individual labelling, packaging and even the warehousing of your axles – of course coordinated with your other processes and requirements.