The production of custom drawing parts at mbo Osswald

Drawing parts are specialized mechanical components manufactured with the highest precision and individually tailored to specific customer requirements. These components are used where conventional standard solutions reach their limits, whether due to size restrictions, material requirements, or special application conditions that demand increased geometric complexity. With the ability to satisfy even the most demanding technical specifications, drawing parts combine precision and flexibility. They offer customized shapes and are made from a variety of materials, including high-strength metals and corrosion-resistant alloys, to function reliably even under extreme loads or in challenging environments.

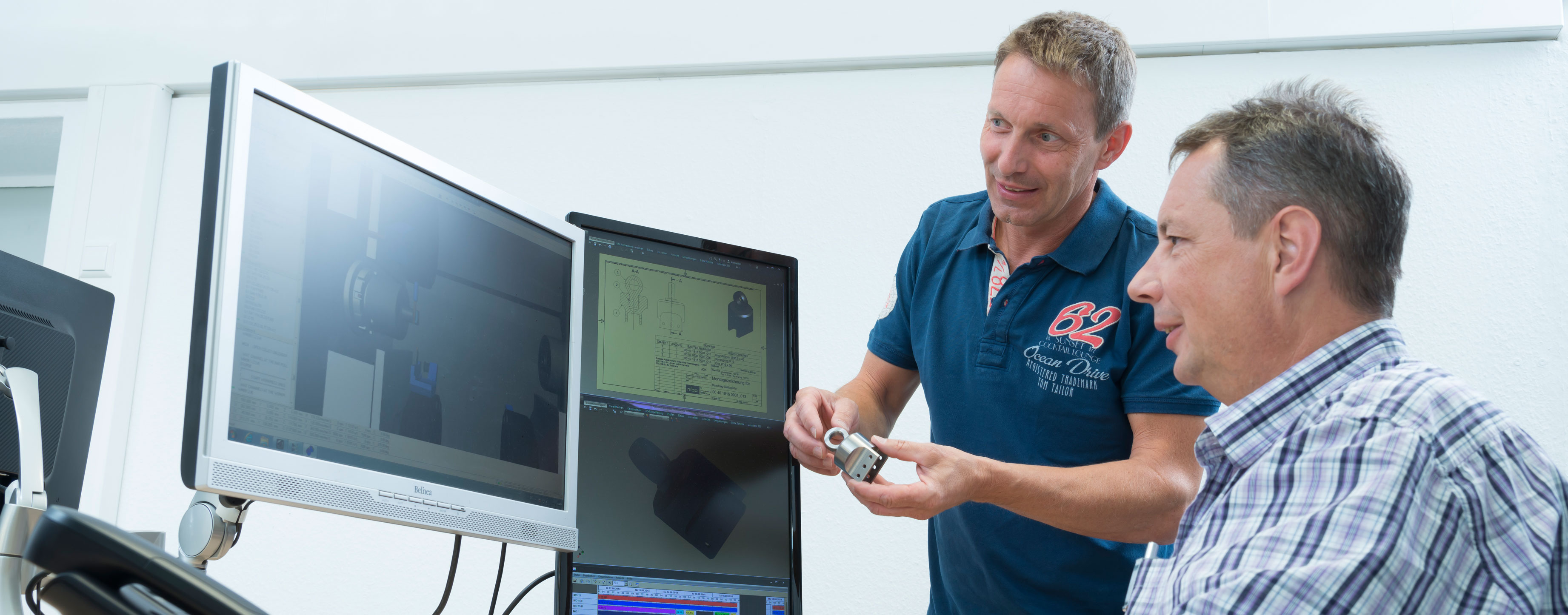

The fulfillment of specific installation requirements and adaptation to spatial conditions are ensured thanks to individually customized dimensions and optimized surface treatments, allowing these components to meet not only functional but also aesthetic requirements. Manufacturing at mbo Osswald relies on the use of state-of-the-art CNC technologies, enabling true-to-detail reproduction of complex geometries and compliance with the strictest tolerances. These technologies allow the production of a wide range of drawing parts, ranging from simple to highly sophisticated designs.

In addition to component manufacturing, we offer comprehensive value-added services. These include precise assembly of modules, specific packaging solutions for safe transport, and, as required, brand-specific markings to improve traceability. Our logistical efficiency ensures that ordered components arrive on time, in the required quantity and quality. With this customer-oriented, integrated service approach, mbo Osswald ensures that drawing parts meet all technical and logistical requirements of our customers and thus contribute to the success of their projects.

Fields of application of drawing parts

Drawing parts unlock solutions for connections, functional integration, and complex engineering projects where standardized components reach their design limits. They are a key element for innovative applications and provide maximum technological freedom and safety across a wide range of industries.

Mechanical engineering

In this industry, custom-drawn parts are indispensable, as they provide highly precise and stable connections between mechanical components. They are particularly used in CNC machines, where they are essential for ensuring the precision of the machinery. A striking example is the use of such parts in spindle and drive technology, where micrometer-precise fits are required to prevent malfunctions and extend the lifespan of the machines.

Vehicle construction

Drawing parts are crucial for the structural integrity and durability of automotive components. They are used in chassis to meet safety requirements by withstanding dynamic forces that occur during braking or cornering. Parts such as control arms or axle stubs, which are subjected to enormous tensile and compressive forces, benefit from custom manufacturing that ensures high strength and precision.

Electrical engineering

Drawing parts are essential here for the securing, positioning, and assembly of circuit boards within complex electronic systems. They contribute to efficient heat dissipation and prevent components from being damaged by thermal expansion or mechanical vibrations. One example of this is heatsink brackets, which help to transfer heat from processors and thus ensure stable operation.

Medical technology

In this sensitive sector, precision and the ability to sterilize are of utmost importance. Drawing parts are used here in surgical instruments and imaging devices, where the highest accuracy and resistance to repeated sterilization cycles are required. Special components made from biocompatible materials such as titanium or stainless steel are central, in order to prevent contamination and ensure patient health.

Renewable energies

Drawing parts are central in wind turbines and solar modules to withstand extreme weather and loading conditions. They ensure the structural integrity of components such as rotor blade holders or frames by protecting them against forces from wind or vibrations. Such parts help to guarantee the efficiency of the systems and reduce operating costs over the service life of the installations.

Furniture industry

In modular furniture constructions, drawing parts enhance stability and flexibility. They enable individual adjustments that facilitate the assembly of variable shelving systems while maintaining the aesthetic appearance of high-quality furniture. In high-end designer furniture, they function as connecting elements that satisfy both functional and visual requirements.

Machining ranges and materials for the production of drawing parts

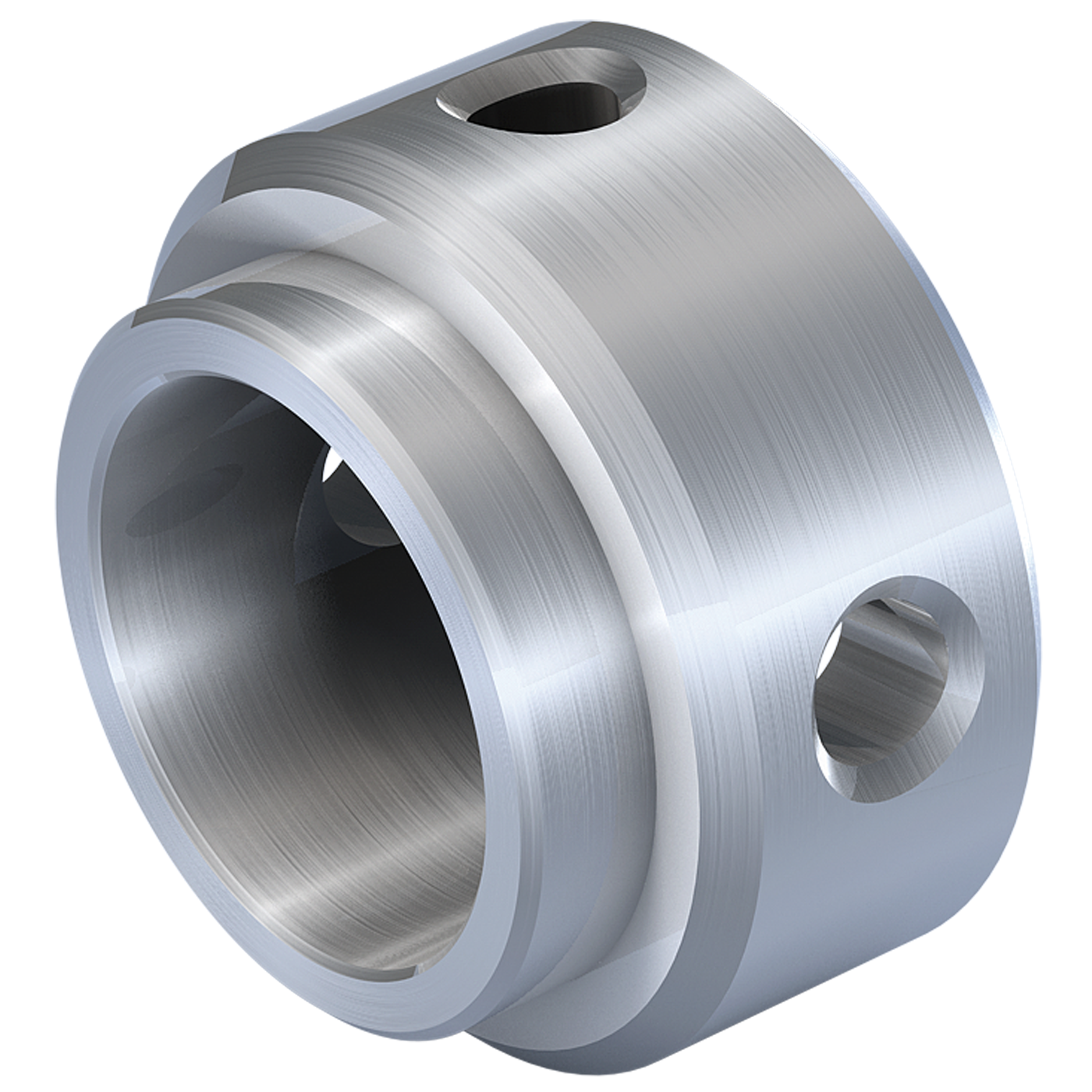

The production of custom drawing parts requires a modern machine park and experience in handling a wide variety of materials and manufacturing technologies. We process round raw parts with diameters from 4 mm to 65 mm, lengths between 5 mm and 350 mm, and produce small, medium, and large series.

Our material selection ranges from common automatic steels for mechanical engineering applications to stainless steel A2 quality and stainless steel A4 quality for corrosive and hygienic requirements, and up to high-strength alloys for aggressive, thermal, or chemical operating environments. With flexible manufacturing facilities, even complex drawing parts with multiple machining steps, challenging tolerances, or industry-specific standards can be produced economically.

Various shapes and lengths for any quantities

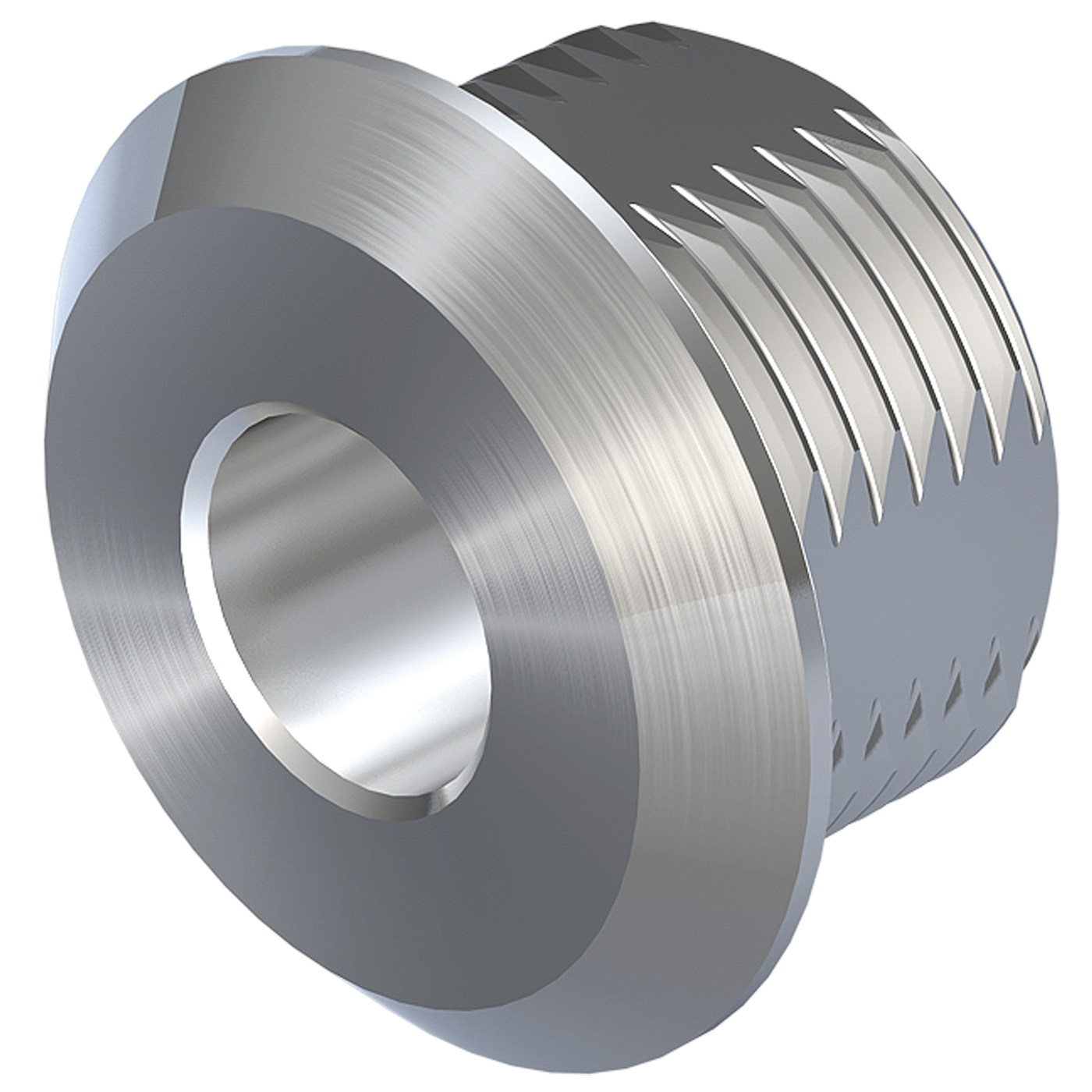

With advanced turning and milling technologies, we precisely adapt each drawing part to your requirements. Freely configurable geometries – from simple bolts through graduated guide elements to toothed, combined, or multiple-processed special parts – are just as possible as a wide variety of lengths, diameters, or shaft shapes.

Thanks to our flexible production planning, quantities, batch sizes, or technical variants can be adapted at short notice to changed construction specifications and project requirements. Whether prototype, short-term test series, or volume production, you always benefit from cost-effectiveness, delivery reliability, and high implementation speed.

The most common materials: steels of variable quality

mbo Osswald offers materials for your drawing parts according to your requirements: undercut steel for classic industrial environments, stainless steels of grades A2 and A4 for all applications with special hygiene and corrosion-chemical requirements (food, chemical, offshore), as well as a wide range of special steels or alloys when strength, temperature resistance, or specific media resistance is required.

This flexibility ensures the long-term stability and low maintenance of your technical solutions—adapted to both highly stressed machines and delicate precision areas.

Drawing parts – diverse machining options

Thanks to our modern machinery and extensive expertise, we manufacture custom drawing parts with a wide range of machining details. These include precise cross-holes, grooves, polygon turning, milling and special contours, spanner surfaces, internal hexagons, metric or inch threads (regular, fine-pitch, right hand, left hand threads), combined machining technologies, and specially designed end shapes.

Customer-specific engravings and markings (e.g. by laser engraving) ensure reliable traceability and documentation of each component – from production to final assembly.

Various surface finishes for your drawing parts

Surface technology decisively determines the load-bearing capacity, material protection, and appearance of custom drawing parts:

Coating

We rely on proven electroplating processes such as zinc plating, phosphating, passivation, and blackening. For special requirements, we offer customized special coatings for protection against aggressive media, optical adjustments, or industry-specific hygiene requirements.

Treatment

Grease-free, oiled or temporary protective coatings are applied depending on the intended use – for perfect assembly, optimized storage, and protection against corrosion.

Mechanical machining

Precise grinding, polishing, and marking processes (laser engraving, coding) increase dimensional accuracy, traceability, and visualize technical features according to customer requirements.

Finishing

Targeted heat treatments (hardening, tempering, nitrocarburizing) specifically improve surface hardness, reinforce critical assembly areas, and increase material resistance even under exceptionally high stress.

The special drawing parts at mbo Osswald

Our particular strength lies in the customized realization of drawing parts exactly according to your specifications – from the design of sophisticated individual components to the series production of highly stressed elements for complex assemblies.

Thanks to consistently coordinated production and inspection processes as well as close, cooperative support, every drawing solution is perfectly tailored to functionality, assembly and maintenance friendliness, and the planned budget. Even in the event of design changes, short-term batch adjustments, or tight project schedules, we offer flexible manufacturing and logistics processes to ensure your products are always ready for use.

Specialist for drawing parts: individually for you!

From technical consulting to precise CNC manufacturing, value creation through additional assembly and packaging, up to complete documentation and flexible shipping or storage solutions, we stand by your side as a full-service partner.

Our offering covers all project stages—from feasibility studies and the production of initial samples, through ongoing quality control, to integration into your processes. Short communication channels, qualified experts, and digital interfaces provide maximum transparency, on-time delivery, and efficiency—ensuring your drawing parts are delivered on time, with guaranteed quality, and exactly as you require.