The manufacture of custom sleeves at mbo Osswald

Sleeves according to drawing are specialized, cylindrical components that are used in many ways as spacers, guiding elements, protective sleeves or as precise bearing seats. In industry they are indispensable when it comes to directing movement, creating defined distances or protecting sensitive components. Each customer application places specific demands on the material, surface finish or dimensional design – therefore our sleeves are deliberately designed and produced according to individual specifications. By using modern turning and milling centers, mbo Osswald can realize both very simple and complex sleeve geometries with high repeatability and tight tolerances. A wide range of materials and surface options is available to make the sleeves suitable for different environments – from extreme temperatures to aggressive chemicals. Regardless of the scope – single piece, prototype or large series – we ensure for every sleeve that all technical characteristics are met using state‑of‑the‑art manufacturing technology and a quality‑focused implementation.

Applications of sleeves according to drawing

Sleeves make an indispensable contribution across a wide range of industries and applications. The main advantage of custom manufacturing is the ability to tailor components precisely to spatial, dynamic and material-related requirements - regardless of the complexity of the assembly or particular influences. Custom-made sleeves ensure reliable performance wherever standard solutions hit installation, load or hygiene limits.

Mechanical engineering

In mechanical engineering, sleeves are used to guide axles, shafts or pins, to act as spacers between structural components, or to reliably protect heavily loaded bolts and bearing points. They often serve as precise spacers between rotating and stationary parts, enable defined assembly configurations and support the smooth movement of mechanical assemblies - for example in packaging machines, robot axes or in precision assembly lines.

Vehicle manufacturing

In automotive and commercial vehicle engineering, special sleeves are crucial for secure assembly conditions in chassis, braking systems and steering components. In shipbuilding they serve as protective elements or spacers for shaft systems, pipelines or sensitive connection parts and ensure long-term stable performance even under high vibration and corrosive conditions. Precise manufacturing, especially according to drawing specifications, guarantees that all requirements for load capacity, fit and resistance to external influences are reliably met.

Electrical engineering/Electronics

In electrical engineering, custom-made sleeves serve as support and spacer sleeves for printed circuit boards, contacts, or heat-dissipation elements. Thanks to their compact and individually adaptable design, they enable secure, space-saving arrangements even in densely packed devices, control housings, or electrical switch cabinets. Special materials or surface treatments prevent unwanted conductivity, oxidation, or wear.

Energy generation

Sleeves are found at key points in wind power and photovoltaic installations, where they secure structural connections and bearings and guide system segments relative to one another. The precisely tailored configuration guarantees safe operation – even under sustained mechanical loads, temperature fluctuations, or extreme weather. Their design is determined by requirements for durability, mechanical strength, and specific surface protection.

Food and chemical industry

Where hygiene and corrosion protection are top priorities, sleeves made of stainless steel or special chemically resistant materials are required. They enable safe, hygienic contact between system components and facilitate thorough cleaning, e.g. in mixers, dosing units or filling systems. For aggressive media or high temperatures, special materials and defined surface finishes are also available.

Construction and building technology

Sleeves perform a variety of functions in construction and building services: they serve as spacers, compensate for tolerances and act as assembly aids, protect edges and threads, guide cables and pipes neatly through components, and make disassembly easier. As anchor or dowel shells they secure fastenings in concrete, improve sound insulation and fire protection, and reduce corrosion risks.

Machining capabilities and materials in sleeve manufacturing

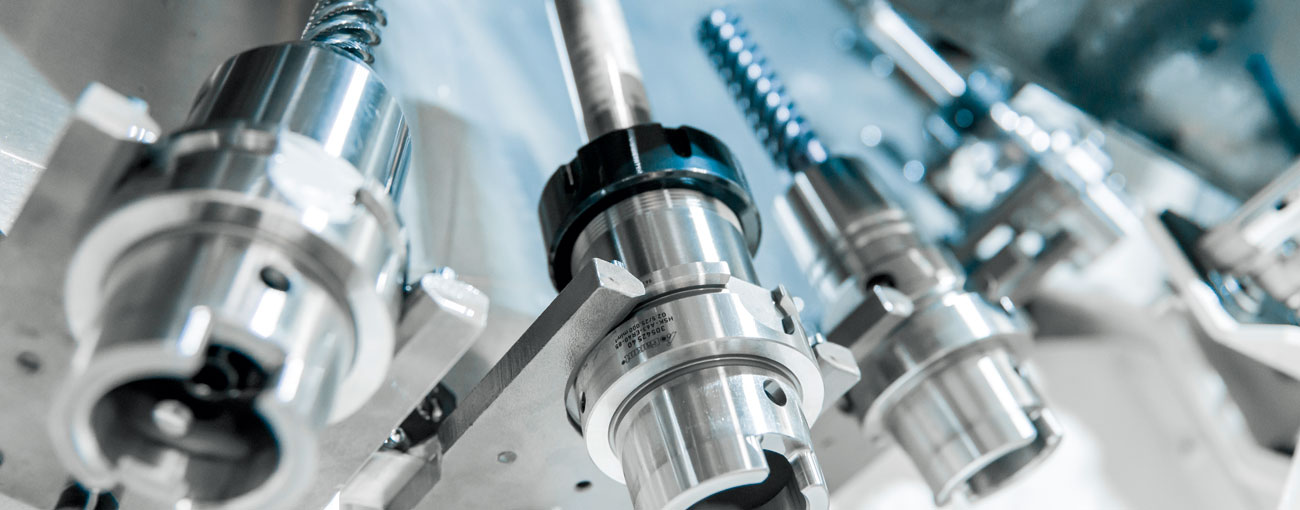

For the production of your custom sleeves, we have a flexible machine park at our disposal that covers all common diameters from 4 mm to 65 mm and lengths between 5 mm and 350 mm. This allows single pieces as well as medium and large series to be manufactured precisely, economically and on schedule.

Our material selection includes undercut steel for classic industrial applications, stainless steel in A2 and A4 quality for uses with special hygiene or corrosion-resistance requirements, and a wide range of special and high-performance steels when maximum strength or extreme environmental conditions are required. The selection and matching of materials is always made with regard to your individual requirements for service life, load capacity and operating conditions. Modern machining options also ensure that complex drawing details, special tolerances or combined manufacturing processes can be realized.

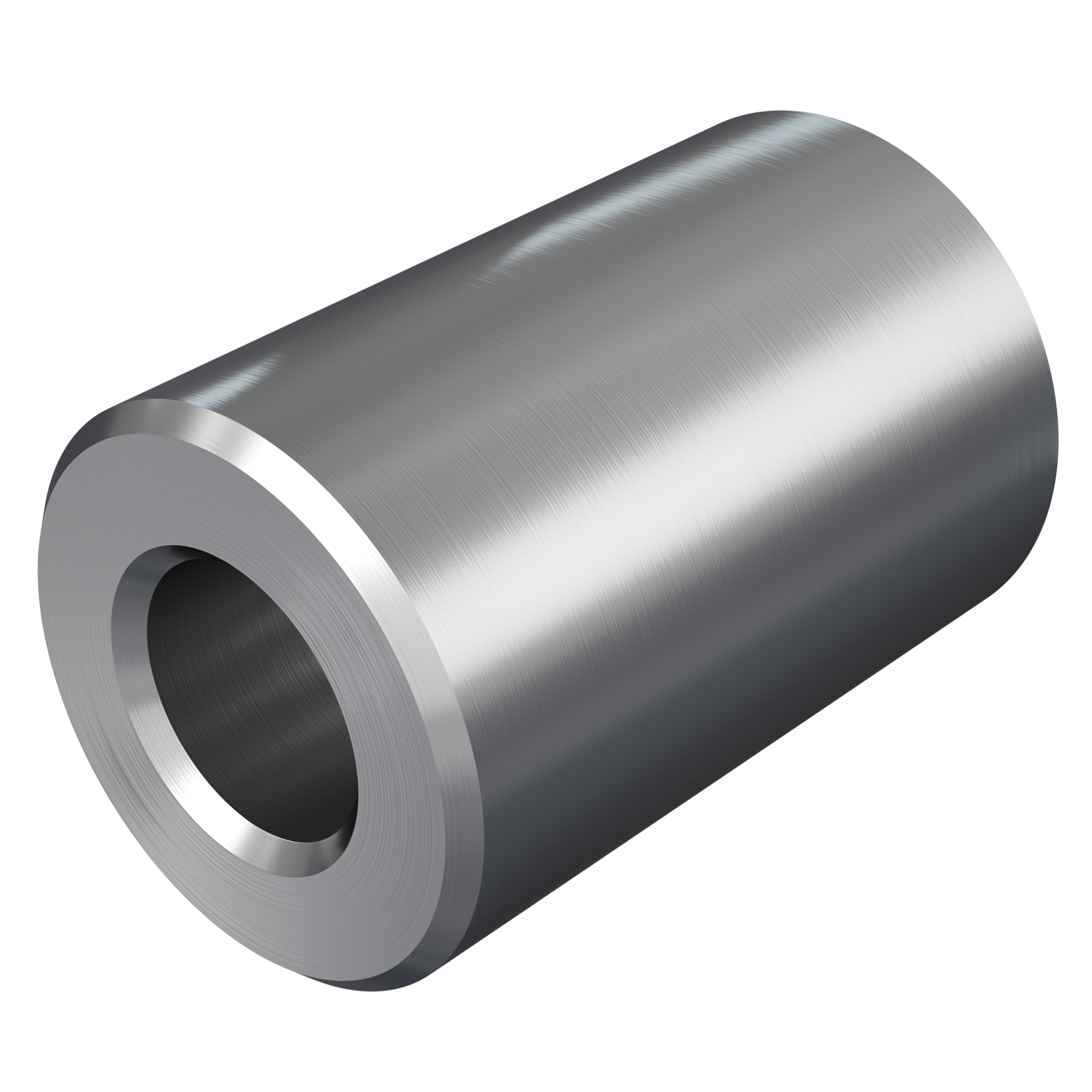

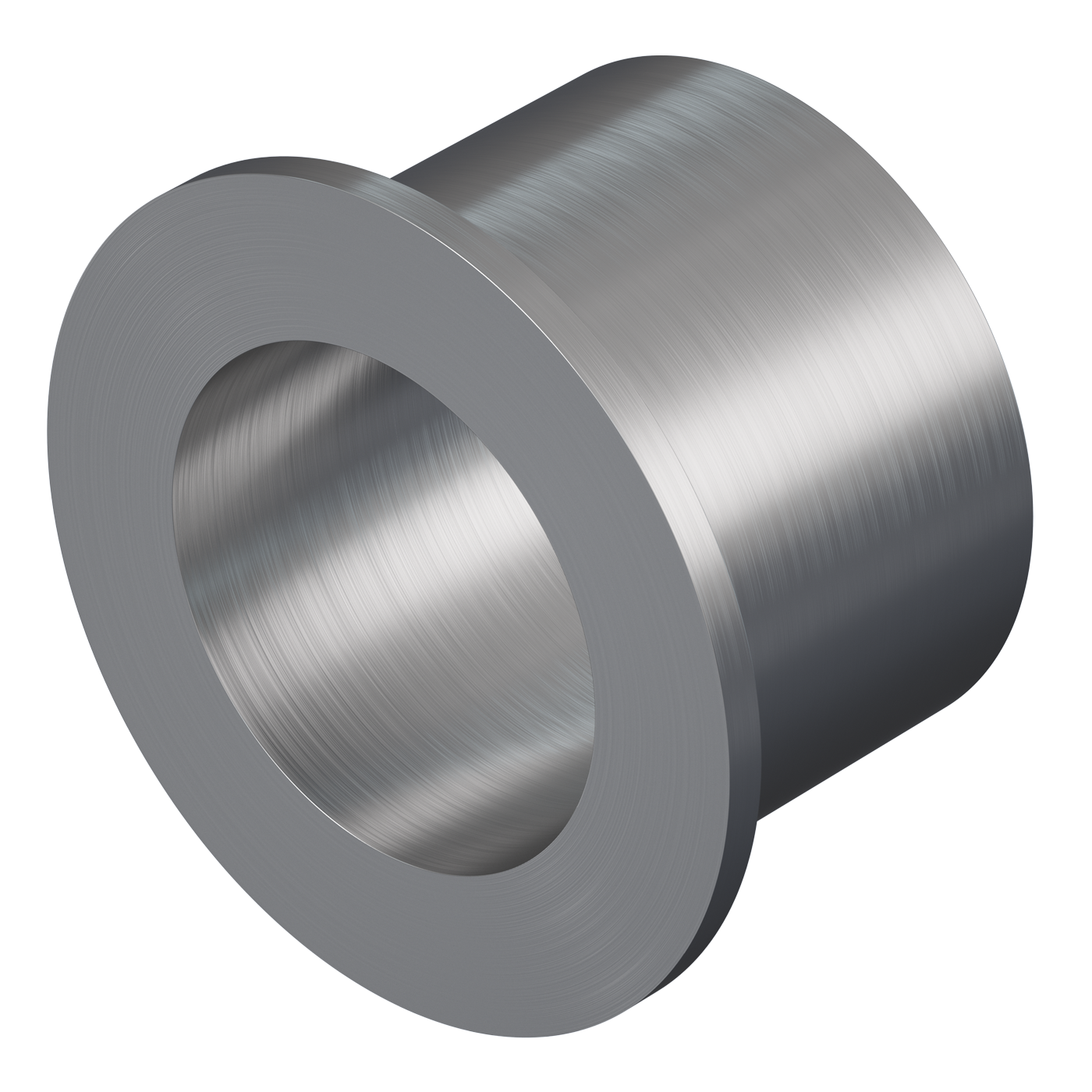

Various shapes and lengths – maximum flexibility

Our production is strictly guided by your specifications and is designed to manufacture any sleeve you require - regardless of shape, length, or material thickness - with exacting precision. We can produce simple cylindrical sleeves, stepped or slotted variants, special mounting sleeves with collar, polygonal (multi-sided) profiles or reinforced collar areas, as well as combination sleeves that integrate multiple technical functions.

Production is scalable: from prototypes and short test series to full-scale production runs, we flexibly adapt quantities, technical variants and delivery logistics to the course of each project. Thanks to computer-aided process planning, short-notice design changes or non-standard batch sizes can also be implemented optimally and without delay.

The most common materials: steels and alloys, depending on the application.

For sleeves according to drawing, we offer a targeted selection of field-proven materials. Single items and series parts are manufactured from undercut steel when high machinability and stable mechanical properties are the primary concerns. For particularly demanding, wet or aggressive operating conditions, stainless steels of class A2 or even A4 are used, for example in the food sector, in marine applications or in chemically exposed environments.

Additional specialty and high-strength materials complement the range for projects that require temperature resistance, extreme loads or high chemical resistance. Together with you we determine the ideal material - always in a perfect balance of technical functionality and cost-effectiveness - so that your sleeve precisely meets the requirements of your industry.

Sleeves according to drawing – Extensive machining options

To achieve an exact fit and a wide range of applications, numerous machining options are available for all sleeves produced to drawing. These include precise cross holes, grooves, milled features, multi‑sided machining, various special contours such as spanner surfaces, special end forms, female or male threads in metric and inch versions (also as fine-pitch threads, left‑ or right hand threads) as well as elaborate special geometries.

Thanks to modern manufacturing technology, complex combined machining operations and delicate details, for example sealing grooves or special fit areas, can also be implemented reliably. For traceability and documentation requirements, we also offer customer‑specific engravings or markings (e.g. by laser engraving or stamping).

Various surface finishes for your sleeves according to the drawing

Targeted surface finishing plays a crucial role in the longevity, reliability and appearance of sleeves according to drawing – regardless of whether they are used as spacers, guiding elements or protective parts. Depending on the application and environmental requirements, various solutions are available to optimally protect the sleeve against wear, corrosion, chemical attack or mechanical stress. The correct choice of surface treatment therefore not only ensures technical performance but can also improve ease of assembly, hygiene and the desired aesthetic properties.

Coating

We offer a wide range of electroplating processes – from conventional zinc plating through phosphating and passivation to blackening. On request, technically or visually modified surfaces for special requirements can be realized, ensuring the sleeve is optimally protected against corrosion, abrasion or aggressive media.

Treatment

Whether as a grease-free version for hygienic applications, with a defined oil film to facilitate assembly, or as temporary corrosion protection: Each variant is precisely tailored to your area of application to simplify assembly effort, storage and handling.

Mechanical processing

For perfect function and appearance, we offer precise grinding for excellent surface quality, individual engravings or markings for documentation and traceability, as well as special polishing or fine finishing for particular visible parts.

Finishing

By targeted heat-treatment measures such as hardening, quenching and tempering, or nitrocarburizing, we specifically improve surface properties and strength, increase wear and corrosion resistance, and - depending on your requirements - ensure maximum protection and service life.

The specialty: sleeves from mbo Osswald

Our expertise lies in the custom manufacture of a wide variety of sleeves for every application profile. From prototypes and the fine-tuning of challenging special series to large-scale production, we produce precisely fitting single and combined sleeves - tailored to length, inner diameter, flange, groove, thread, multi-sided profile or special contour.

Our product portfolio includes simple spacer sleeves, highly precise guide sleeves, ready-to-install combined parts for special machine construction, and sophisticated hygienic sleeves. We can also flexibly implement adjustments to rapidly changing project requirements or short-term technical changes. Each order benefits from decades of technical experience, modern machinery and a solution-oriented project management. The result: your sleeve fits from the outset - technically and economically.

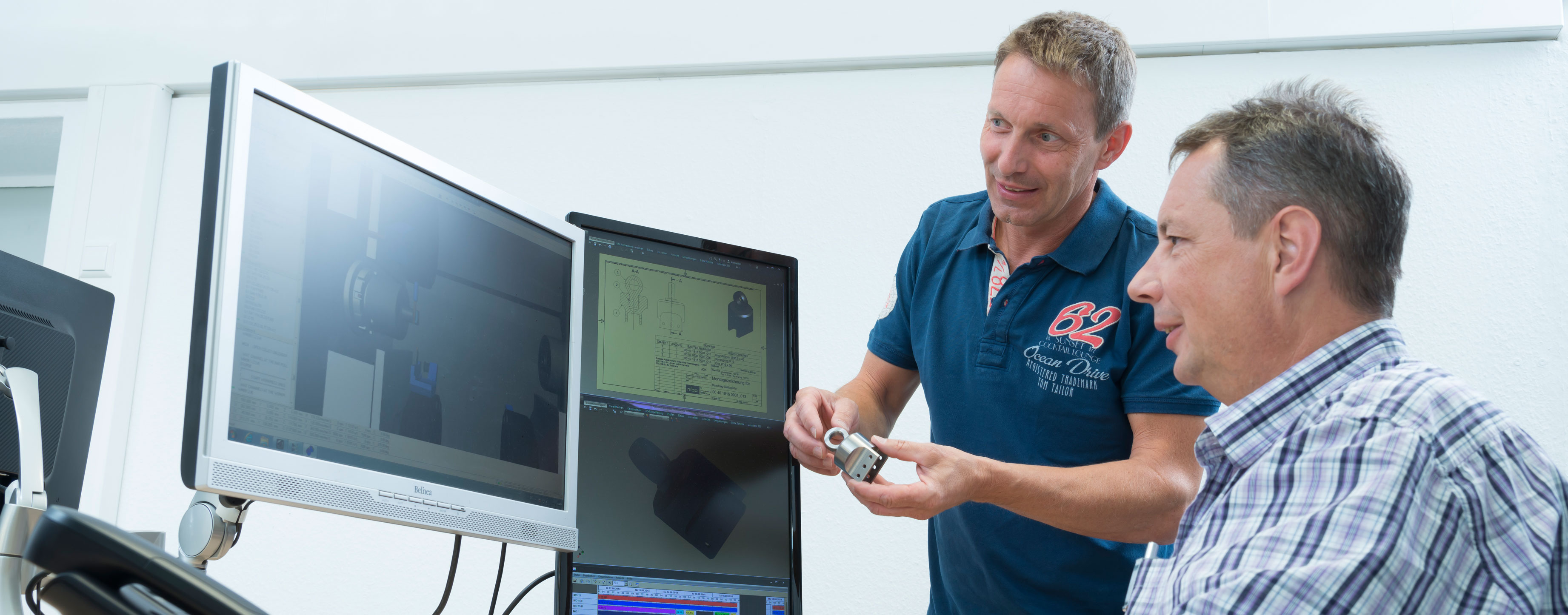

Comprehensive service for sleeves according to drawing

mbo Osswald stands for process safety and a cooperative full-service approach for every sleeve project. From consulting and feasibility assessment through drawing optimization and material selection to on-time, quality-compliant production, final inspection and shipping, we competently support your project throughout. In addition, we offer numerous supplementary services-such as assembly, special packaging, custom labelling, inventory management and blanket order processing. A dedicated contact person, rapid coordination, flexibility regarding quantity and delivery changes, and well-planned logistics ensure an efficient workflow from first contact to the integration of your sleeve into your assembly processes - everything from a single source, with maximum transparency and control.