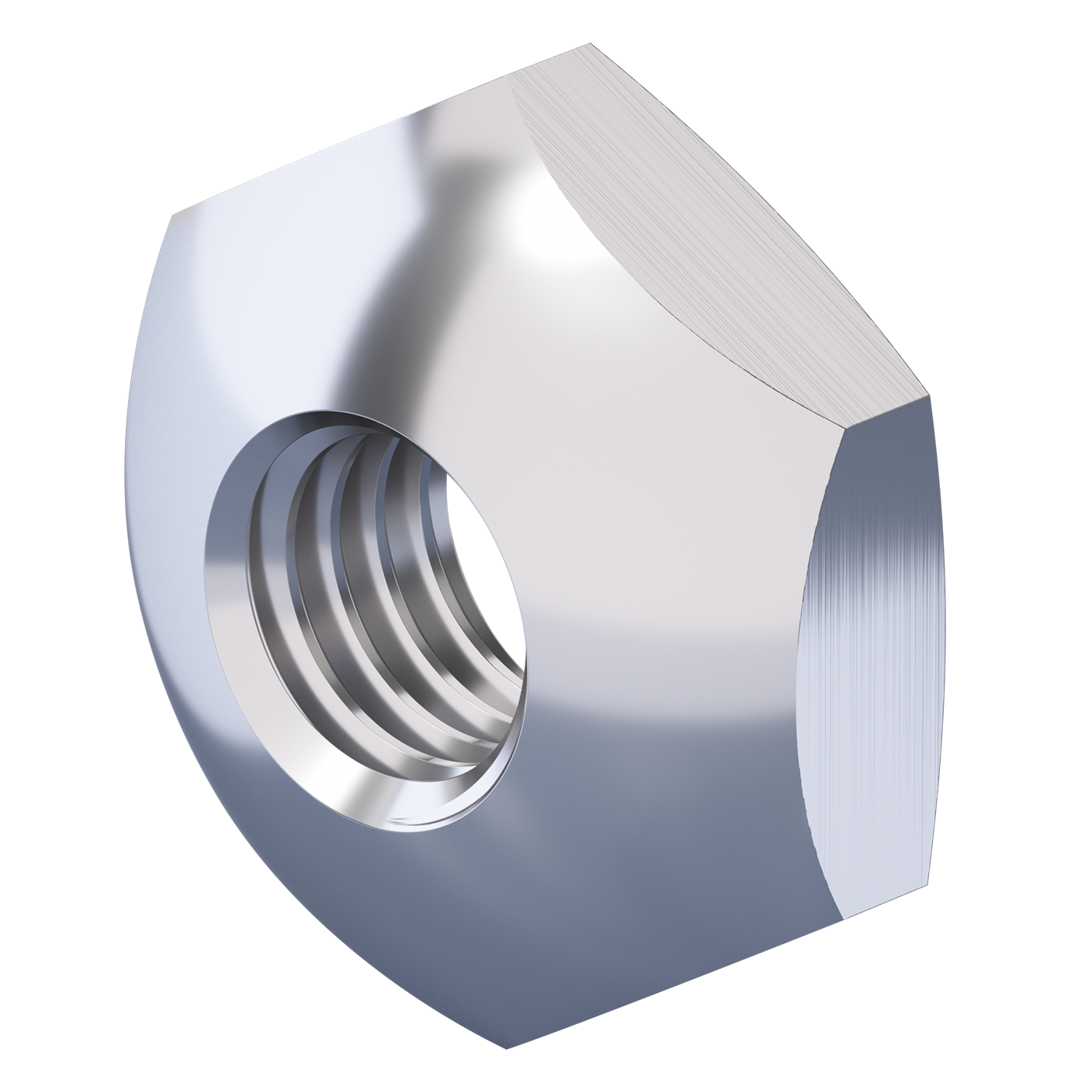

The manufacture of individual special nuts at mbo Osswald

Turned special nuts are technically sophisticated fasteners used wherever standard solutions are insufficient due to specific requirements for geometry, strength, or material. They not only enable reliable bolted connections, but - through their individual adaptation to drawings, assemblies, or function - offer a high degree of flexibility and application versatility. Whether for confined installation spaces, unusual thread profiles, or special uses in corrosive or heavily stressed environments: at mbo Osswald turned special nuts are manufactured precisely to your specifications, both as single pieces for new projects and in large series for recurring production orders.

Thanks to the latest turning and milling technologies, we implement complex shapes and tight tolerances precisely in the manufacture of your special nuts, thereby ensuring efficiency, dimensional accuracy and process reliability, tailored to the individual challenges of your application.

Applications of turned special nuts

Custom-made special nuts open up new possibilities across a wide range of industries for secure, durable and space-saving fastening solutions.

Mechanical engineering

In mechanical and plant engineering, special nuts connect highly stressed components such as guides, housings, shafts and couplings. They ensure that, even under strong vibrations, varying loads or extremely demanding assembly situations, a form-fitting and precisely mating bolted connection is always maintained. In particular, for special machines, precision shafts or moving bearings, tailor-made special nuts are a guarantee of operational reliability and ease of maintenance.

Vehicle construction

In the automotive and commercial vehicle sectors, turned special nuts ensure secure connections on axles, chassis and suspension systems, where high dynamic loads occur and high component strength, corrosion protection and straightforward disassembly are crucial. They are also used in mounted components, fuel and exhaust systems or frame rails, where a combination of strength and easy accessibility is required.

Electrical engineering/Electronics

In the area of control cabinets, PCB assemblies and assembly installation, special nuts provide compact connections that enable both securing and insulation. Their precise manufacture also ensures a reliable, vibration‑resistant fastening of sensitive components even in miniature systems or tight installation spaces.

Medical technology

Special nuts are developed specifically for medical devices, analytical apparatus, and surgical instruments where precision and resistance to frequent cleaning or sterilization cycles are fundamental. Special high‑grade stainless steels or corrosion‑resistant alloys are often used here to optimally meet hygiene requirements and material purity standards.

Renewable energy

In wind turbines, solar panel mounts, or structural elements in plant engineering, turned special nuts provide secure, weather- and vibration-resistant assembly connections. They ensure reliable operation under constant exposure to temperature fluctuations and UV radiation without compromising strength or corrosion protection.

Furniture industry

Modern furniture and construction technology uses special nuts for concealed or visible fastenings, modularly adaptable frames and particularly durable connection points. Their precise manufacture allows harmonious integration into design solutions and provides a high level of aesthetics while simultaneously improving the ease of disassembly.

Machining operations and materials in the manufacture of special nuts

Our production is designed for the flexible processing of all diameters from 4 mm to 65 mm and lengths from 5 mm to 350 mm in all common batch sizes, from prototypes and initial sample production to medium runs and series production. Depending on the application requirements, we use undercut steel when high machinability and cost-effectiveness are required. For environments with moisture, chemicals or high hygiene standards, alternative alloys as well as stainless steels in A2 and A4 quality or other high-strength special materials are used.

This allows the manufacture of nuts for a wide range of load profiles - for example heat-resistant, seawater-resistant or highly stressed assemblies - with maximum service life and minimal maintenance. Production is always carried out with due regard to individual drawing tolerances and any relevant industry-specific standards.

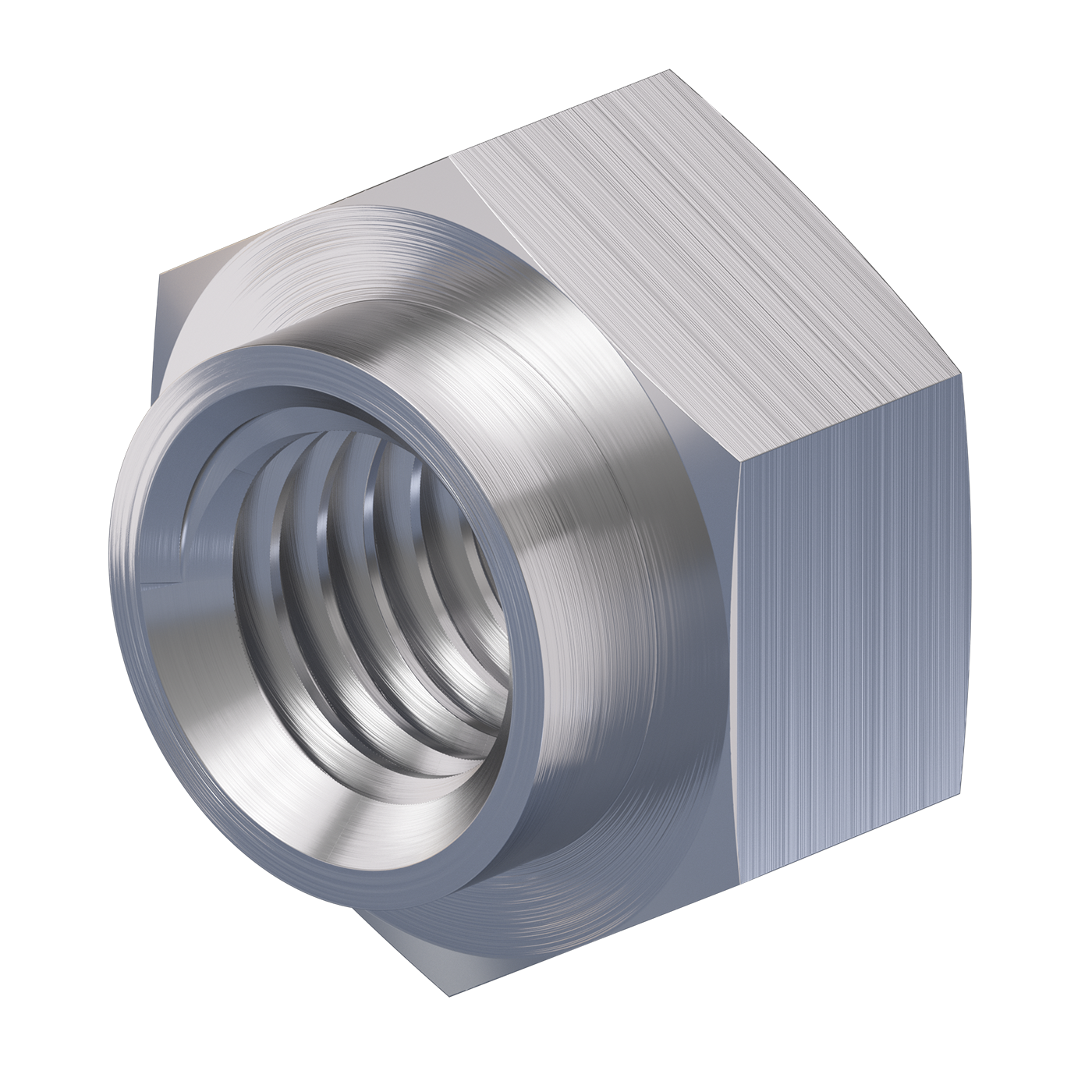

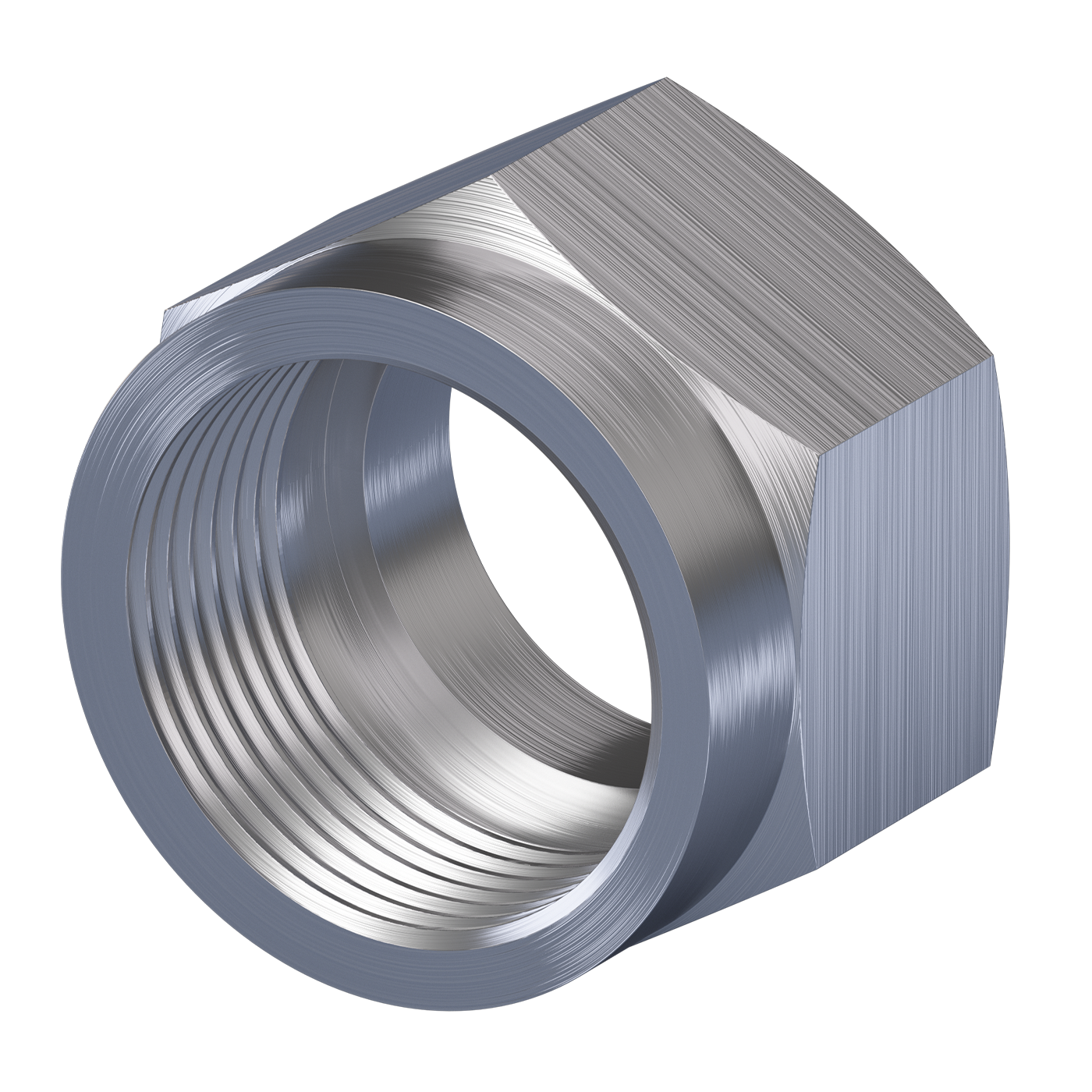

Various shapes and lengths

The range of possible special nuts is virtually unlimited. We manufacture a wide variety of geometries for you: whether classic six-sided nuts with special punching, internally contoured nuts with multiple flats, a stepped flange, or a combined head-/shank design – all configurations are scalable and are implemented individually for each project in the desired length, thread type and external geometry.

Likewise, designs with special fits, multiple functional areas, slots for assembly aids or targeted reinforcement at highly stressed points can be produced reliably. Our flexible manufacturing guarantees the adaptability you require – from the rapid production of a single part and short pilot runs to annual production with changing versions.

The most common materials: steels and alloys according to application profile

We advise you and together select the right material for each special nut - tailored to the environment, mechanical stresses and required service life. Undercut steel is used for conventional connections, while stainless steels A2 or A4 are employed wherever hygiene and corrosion resistance are paramount - for example in medical technology, the food industry or plant engineering.

In addition, we process special steels with high toughness, strength or media resistance for extreme applications, thermal loads (e.g. hot-air systems) or aggressive process environments (e.g. chemical plants). This ensures that each special nut becomes the optimal link between components under the specific required boundary conditions.

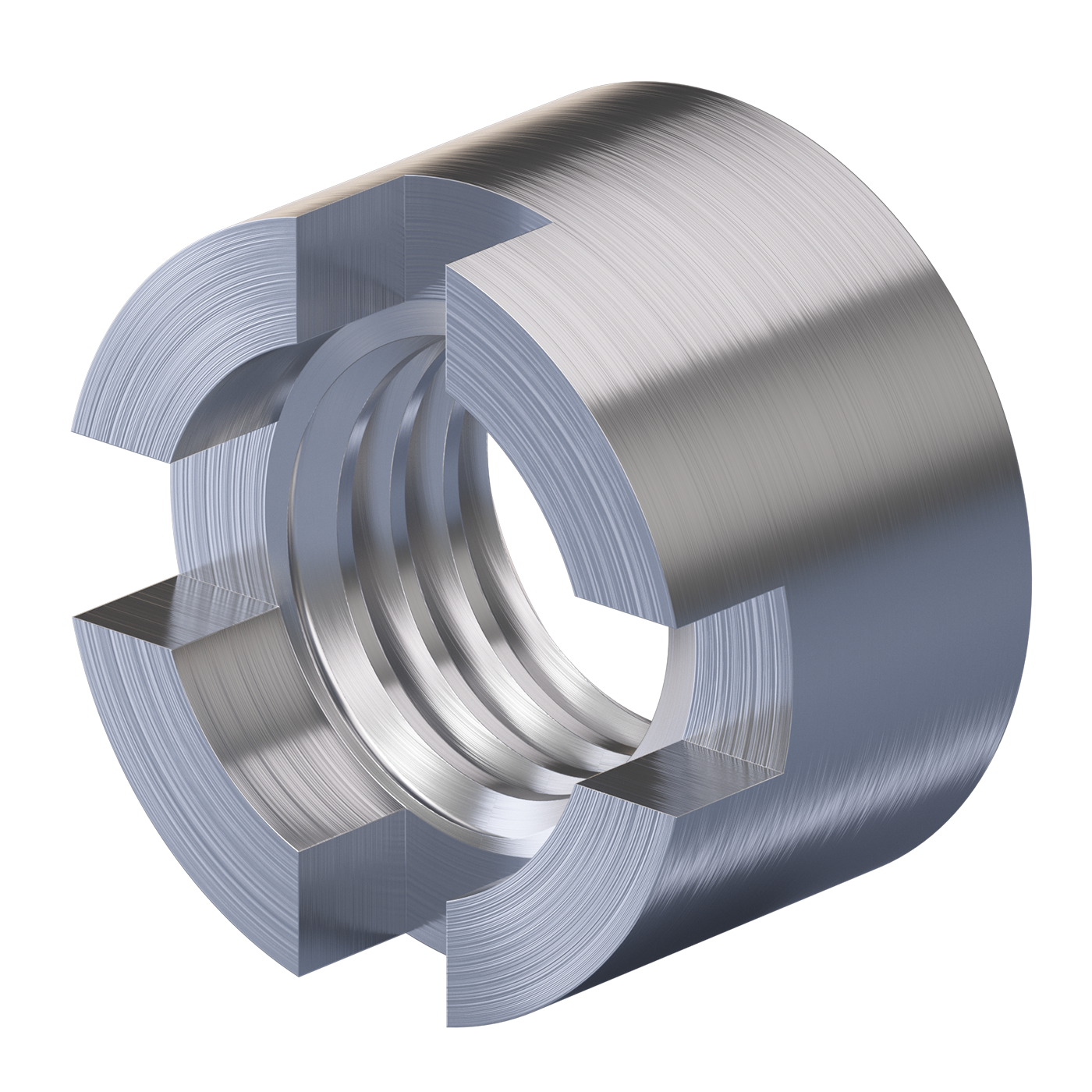

Special nuts – extensive machining options

Our turning and milling technology opens up a wide range of manufacturing details: thread production in both metric and inch standards (regular and fine-pitch threads, right-/left-hand threads), cross holes, grooves, special milling for custom connections, polygonal profiles, spanner surfaces, internal hex, special collars and bespoke end geometries.

Depending on the requirement, we combine multiple manufacturing technologies and process complex special forms, sealing and guide contours, or specific markings (e.g. laser engravings, decorative grooves, codings), so that each special nut precisely meets the application’s functional, assembly and documentation requirements.

Various surface finishes for your special nuts

For optimal functionality, corrosion protection and aesthetic requirements, we equip your special nuts with the appropriate surface finish:

Coating

Electroplating processes such as zinc plating, blackening, passivation or phosphating provide durable protection against corrosion, offer long-lasting color or hardness options, and meet a wide range of technical and visual requirements. Special coatings can be applied on request, depending on the intended use and customer specifications.

Treatment

Grease-free delivery for hygiene applications, a defined oil film for easy assembly, or a temporary coating as transport protection - every detail is individually adapted to the subsequent assembly process and your logistics.

Mechanical processing

Precision grinding, individual marking by laser engraving or stamping for quick identification, documentation and traceability of your nuts - the surface remains technically and visually high-quality.

Finishing

Heat treatments such as hardening, tempering or nitrocarburizing further enhance functional reliability and the surface’s resistance to mechanical and corrosive influences – ideal for demanding, safety-critical industries.

The special-purpose nuts at mbo Osswald

Our focus is on the precise manufacture of special nuts exactly according to your drawing or technical specification. Whether a single piece, pilot run or large order: we provide you with maximum design freedom, support for complex geometries, compliance with industry standards and specific material selections – all processed on modern CNC systems with stable processes.

From the classic hexagon nut to multi-stage, function-integrated special nuts and sophisticated aesthetic custom solutions, we realize everything your design requires. We also efficiently accommodate short-notice design changes, special assembly conditions or small batch sizes, delivering consistent, process-secure quality.

Specialist in turned special nuts: precision and full-service

We offer a comprehensive service, from the initial idea to the final integration of your special nuts. Our services include feasibility studies, advice on technical design, individual production planning, material selection, drawing and production optimization, as well as on-time, quality-assured production.

On request, we organize assembly, special packaging, customer-specific labeling, or support you with flexible warehousing and digital interfaces to your purchasing system. Personal contact with designated contacts, the shortest lines of communication, and competent advice throughout the project process guarantee that your special nuts always arrive on time, in verified quality, and exactly as you require.